Electronics & Computing

Next: Recycling Plattics

Can electronics be manufactured locally?

… from plastics?

Introduction and Future Trends

There is big potential to reuse old electronics devices like phones, game consoles, smart speakers, TVs etc. as the decentralised computing infrastructure of the future to provide computing services like data processing (CPUs), data storage etc. Or be nodes in some new services like a variant of blockchains.

This requires ability to completely change the firmware of devices to give them a new life as part of the shared mesh behind the digital world. Most commercial products make this difficult due to security and commercial reasons (always be buying the latest..), but open source designs have more freedom of choice.

Decentralisation requires that computing and electronics to be locally manufactured. We’ll take a look at two potential ways.

Printed electronics is a technology where conducting polymers are used to print wires, capacitors, resistances, batteries and even solar cells. The technology is still in starting phase but promises together with locally captured synthetic hydrocarbons and flow chemistry already discussed to provide an answer for local electronics manufacturing. More performant computing need central processing units (CPUs). Some research has been made to manufacture CPUs from plastics. See below for more.

On the longer horizon, generative design is needed to change from standardised open source designs to a fleet of different designs all producing the same result. The logic is as follows:

As central processing units are driving all of the future digital universe, this makes them a single point of failure and a big risk factor. Only a few architectures today totally dominate the landscape. To overcome this, the design process needs to be changed so that every CPU (or very batch of a few thousand) of the future will be different in some way. This makes penetration attempts much more difficult as every attempt is against a different design. This is essentially how nature works giving us all a unique DNA that leads to differences in how our body responds to diseases and parasites. This could be achieved when generative design principles are applied and letting computers design new CPUs. This is what we names earlier silicon individualism.

But onto printed electronics and plastics CPUs.

Printed Electronics, plastic microcontrollers

Inks can be made conductive by adding graphite or other conductive materials. Electronic devices like thin film transistors, capacitors, coils or resistors can be made with it using traditional printing technologies like inkjet printers or offset lithography or gravure. This is significantly cheaper than production of traditional electronics.

Printed electronics is today used in applications like flexible displays, smart labels, decorative and animated posters, and active clothing where performance is not so critical.

Some future uses of printed electronics are for example various ways to convey information to people in homes or in public places. Say a wall paper that communicates environmental information such as temperature, weather prediction (rain, cloud, sunny) or pollution levels outside to users in the morning. This type of functionality is called ambient computing. These active surfaces can evolve to interactive games or gamified rehabilitation applications. All of these could be based on relatively simple logic locally designed, made and used.

Speed is expected to increase and costs come down in future meaning printed electronics can find its way to other applications where better but still moderate computing capacity is needed. For example, home appliances like coffee makers, washing machines, electric stoves, food processors, juicers, timers. These do not need to be connected to Internet and their logic is simple. Silicon chips inside appliances could be replaced with locally printed logic.

One additional use for printed electronics is to make organic solar cells. The whole Unfactory concept could be made recursively from itself (“we print solar cells that provide energy to capture carbon and split water to hydrogen (and oxyge), then Fisher-Tropsch process creates feedstocks that via flow chemistry are made to produce more complex materials used to produce 3D printers and conductive inks to “print” solar cells that in turn…”).

Compared to silicon-based devices, polymer solar cells are lightweight (which is important for small autonomous sensors), potentially disposable and inexpensive to make, flexible and have less adverse environmental impact. Polymer solar cells also have the potential to be transparency and used on in windows or walls. However currently the performance of printer solar cells is far behind mass manufactured silicon cells.

There is development for building microcontrollers on flexible plastic material (e.g., plasticARM). Their speeds and processing power is limited compared to silicon but they are following a similar exponential improvement curve but some 30 years behind. They are extremely cheap to produce and allow easy customisation. Plastic is also impact resistant. As they are printed on thin, flexible plastic sheets, these microcontrollers can be integrated to all types of form factors. A key challenge today is the power consumption and heat dissipation in the plastic.

https://www.eenewsembedded.com/news/32-bit-plastic-microcontroller

https://en.wikipedia.org/wiki/Organic_solar_cell

https://en.wikipedia.org/wiki/Conductive_ink

https://en.wikipedia.org/wiki/Printed_electronics

The concept of making each batch of processors somehow different by using generative design (this is a passive defence against malicious actors) aka Silicon Individualism was discussed earlier at: https://marttiylikoski.substack.com/p/keystones-silicon-individualism-alpha

Displays

In OLED the light emitter part is very similar to pigments used in printing and the transporter in OLED almost the same as toners in laser printers. This means that in terms of environmental risks it is similar to printing.

This indicates that it is feasible to allow printing displays locally and they can be in any shape.

Last but not least, from the department of improbable future, we are product to present:

Diamond electronics

One day diamonds can replace silicon in semiconductor material. Carbon is on the same column in period table as silicon meaning it has same number of outer electrons.

Before going further, a little explainer on transistors that are the basic building block of processors. There are many types of transistors but here we focus only on one particular type for brevity (MOSFET) and in particular n-type MOSFETS.

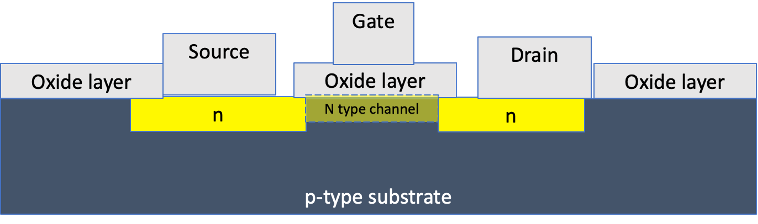

Transistors really just have three parts: source, drain and a gate. Transistor acts as a switch where voltage applies to the drain controls up flow of current between the source and the drain.

The gate in a MOSFET is separated from the channel by a thin insulating layer of oxide. MOS (metal-oxide-semiconductor) in the name comes from that. When a voltage is applied to the gate, it creates an electric field that changes the conductivity of the channel. If the voltage is high enough, it will "open" the channel and allow current to flow from the source to the drain. If the voltage is too low, the channel will be "closed" and no current will flow.

Silicon has 4 electrons in its most outer electron band so it can pair in covalent bonds with 4 more silicon atoms to a (diamond like) structure where energy levels of electrons are at lowest level. This makes pure silicon an insulator.

In an n-type semiconductor, the impurity atoms have one more valence electron than silicon, which allows them to donate extra electrons to the conduction band, creating an excess of carriers (i.e., impurity atoms have 5 electrons on outer orbit). N-type silicon can be doped with phosphorus (P), arsenic (As), or antimony (Sb).

In a p-type semiconductor, the impurities have one fewer valence electron than silicon, which creates a deficiency of electrons, or "holes," in the valence band.

The band gap of silicon is the energy gap between the valence band (electrons in ground state in the atom) and the conduction band (where electricity can flow and electrons are in exited state) . The voltage applied to the gate of a MOSFET can change the energy of the carriers in the channel by shifting the position of the valence and conduction bands. If the voltage applied to the gate is high enough, it can create an electric field that is strong enough to shift the bands, allowing more carriers to cross the band gap and increase the conductivity of the channel. This is how the voltage applied to the gate of a MOSFET is related to the band gap of silicon.

In silicon the band gap is 1.12 eV (electron volt).

A semiconductor with a large value is called a wide-band-gap semiconductor. SiC (Silicon Carbide) and GaN (Gallium Nitride) are wide-band-gap semiconductors. Wide-bandgap semiconductors permit devices to operate at much higher voltages, frequencies, and temperatures than conventional semiconductor materials like silicon and gallium arsenide.

For more: https://en.wikipedia.org/wiki/Wide-bandgap_semiconductor

Diamond is also an insulator as it has same outer electron structure as silicon. Diamond is also semiconductor that has a band gap of the order of five electron volts versus say 1.13 eV in silicon or three electron volts with gallium nitride. This means diamond electronics can operate at even higher temperatures, frequencies and voltages.

For this to work we would need to produce diamond thin films. Currently we cannot yet produce large enough wafers for microelectronics processing. But as the only thing that you need to make diamond is carbon this lends *in principle* itself easily to decentralisation. The question is whether the technology needed is too specialised to be widely deployed in a decentral fashion and what would it mean.

Still, one additional material to look for as a semiconductor is diamond and it has many benefits.

Next: Recycling Plattics